Photonic Integration Platforms: Nomenclature and Comprehensive Technical Description

Introduction

Photonic Integrated Circuits (PICs) stand at the cutting edge of optical and photonic innovation, enabling the development of highly efficient, scalable, and compact solutions for a multitude of applications. These applications range from high-speed data communications and RF photonics for 5G networks to LiDAR systems, quantum optics such as quantum key distribution, and advanced sensing systems. The evolution of PICs is intrinsically linked to breakthroughs in material science, fabrication methods, and the seamless integration of passive and active photonic components on a chip-scale platform. This article delves into the technical details of emerging photonic integration platforms, explaining their properties, fabrication methods, and roles in contemporary scientific and industrial contexts.

Classification of Photonic Platforms

Photonic integration platforms can be broadly classified into passive and active materials, each serving specific roles in the creation of photonic circuits. Passive substrates, characterized by their wide bandgap, are optimized for waveguiding and low-loss optical propagation without intrinsic light generation or amplification capabilities. Examples include materials like silicon, silicon nitride, and silica. On the other hand, active materials, which include semiconductors such as indium phosphide and gallium arsenide, enable light generation, modulation, amplification, and detection, often leveraging their direct bandgap properties. This division into passive and active materials provides the foundation for tailored photonic solutions that address various requirements for wavelength ranges, thermal and mechanical stability, and integration complexity.

Detailed Platform descriptions

● Silica (SiO₂): Silicon dioxide serves as one of the earliest and most widely adopted platforms for photonic integration. Known for its low refractive index and minimal birefringence, SiO₂ operates across a broad transparency range, spanning from 400 to 2100 nm. Its low optical loss, typically below 0.1 dB/cm in the 1300–1700 nm range, makes it an ideal candidate for planar lightwave circuits and erbium-doped waveguide amplifiers. Fabrication processes for SiO₂ include plasma-enhanced chemical vapor deposition (PECVD) or thermal oxidation, with rib and ridge waveguide geometries ensuring efficient coupling with optical fibers. Although highly thermally stable, its relatively large bend radii, due to its low refractive index contrast, limit the platform’s compactness.

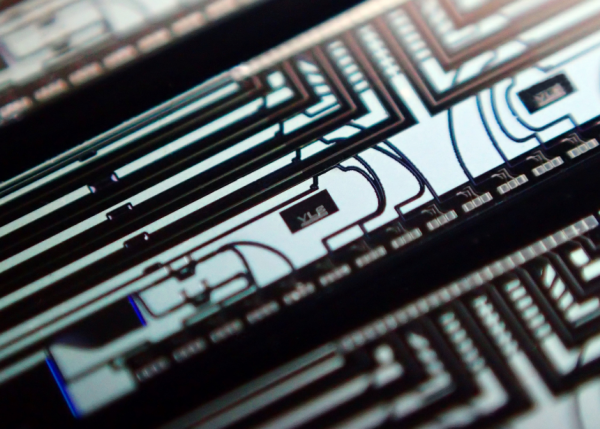

● Silicon Photonics (SiPh): Silicon photonics, utilizing silicon-on-insulator (SOI) wafers, is a leading platform for densely integrated and scalable photonic circuits. The high refractive index contrast between silicon and its insulating SiO₂ layer enables sub-micron waveguide dimensions, facilitating compact designs with tight bend radii. Thin-SOI platforms generally exhibit propagation losses of 2–3 dB/cm, while thick-SOI configurations reduce these losses, supporting applications requiring high optical power. Additionally, doping with elements such as boron and phosphorus allows for the integration of high-speed modulators and photodetectors, enhancing its versatility for telecom and data communication applications. The transparency range of SiPh extends from 1100 nm, making it highly compatible with telecommunication wavelengths defined by the ITU.

● Silicon Nitride (SiN): Silicon nitride distinguishes itself through its low propagation loss and broadband optical transparency, extending from 400 nm in the visible spectrum to over 2300 nm in the infrared. Fabricated through low-pressure chemical vapor deposition (LPCVD), SiN is a robust platform for nonlinear optics, sensing, and low-loss telecommunications. Advances in thick-SiN technology have enabled ultra-low-loss waveguides, with losses as low as 0.8 dB/m. Its relatively low thermo-optic coefficient ensures stability under thermal variations, although its higher thermal expansion coefficient necessitates stress management to prevent performance degradation.

Nomenclature and compositions in Silicon Nitride: Silicon nitride is available in various forms based on its composition and structural properties:

- ➤ Stoichiometric Silicon Nitride (Si₃N₄): This represents the most stable molecular structure with a precise silicon-to-nitrogen ratio.

- ➤ Amorphous Silicon Nitride (aSiN or SiNx): A non-crystalline form of silicon nitride that includes hydrogen bonds, often used for its flexibility in deposition and design.

- ➤ Silicon Oxynitride (SiON): A hybrid of Si₃N₄ and SiO₂, offering refractive indices between 1.45 and 2.0, making it versatile for intermediate applications.

- ➤ Silicon-Rich Nitride (SRN): A variant with a higher silicon concentration, exhibiting refractive indices between 2.2 and 3.0, suitable for high-confinement waveguides and enhanced nonlinear optical properties.

● Aluminum Oxide (Al₂O₃): Aluminum oxide (Al₂O₃) has emerged as a versatile material in photonic integration, offering unique properties that make it suitable for a broad range of wavelengths, from the visible to the mid-infrared (250 nm to over 5 μm). The material’s wide bandgap (5.1–7.6 eV, depending on deposition method) allows for low-loss operation in the ultraviolet (UV) spectrum, addressing critical applications such as atomic clocks, quantum ion traps, and spectroscopy. Al₂O₃’s moderate refractive index contrast with silicon dioxide minimizes scattering losses while maintaining manufacturability for compact device designs.

Fabrication methods for Al₂O₃ include atomic layer deposition (ALD), which achieves extremely low losses down to 1.8 dB/cm at 405 nm, and reactive sputtering, a faster, cost-effective alternative that retains similar performance with losses around 2 dB/cm. These attributes make Al₂O₃ a compelling choice for hybrid integration with platforms like SiN and SiPh. The material’s high rare-earth ion solubility further supports active functionalities, enabling on-chip lasers and amplifiers for applications spanning communications, biosensing, and quantum optics. Aluminum Oxide supports optical amplification through rare-earth ion doping for specific bands.

● Lithium Niobate on Insulator (LNOI): Lithium niobate on insulator (LNOI) represents a groundbreaking advancement in photonic integration, combining the exceptional nonlinear and electro-optic properties of lithium niobate (LN) with state-of-the-art fabrication techniques.

LNOI can be classified into two main categories:

- ➤ Thick-Film Lithium Niobate: Traditional LN platforms rely on bulk materials with proven technologies. They support a broader range of designs but may have higher fabrication complexity and larger feature sizes. This limits their scalability compared to thin-film alternatives.

- ➤ Thin-Film Lithium Niobate (TFLN): Thin-film lithium niobate refers specifically to photonic integrated platforms where LN is deposited on an insulating layer, often silicon dioxide (SiO₂). The term Thin-Film LN (TFLN) emphasizes its use for integrated photonics, while LN on Insulator (LNOI) indicates the LN is supported by SiO₂. Emerging thin-film platforms offer lower Vπ and reduced optical losses. These advantages make TFLN ideal for high-speed modulators and low-power applications. However, thin-film platforms are still in development stages, with Technology Readiness Levels (TRLs) between 0 and 4, depending on the provider. Limitations include a lack of mature process design kits (PDKs) and challenges with polarization control.

Thin-film platforms typically feature compact device footprints, with modulators as small as 6-7 mm in length and widths dominated by routing layers, which may be optimized further. Despite its drawbacks, thin-film LN technologies show promise due to their willingness to share process information and their potential for integration with advanced PIC platforms. On the other hand, Lithium Tantalate on Insulator (LTOI) presents a significant advantage in fabrication efficiency and cost-effectiveness due to its manufacturing process, which closely follows the well-established high-volume commercial production methods of Silicon-On-Insulator (SOI) wafers.

This alignment enables scalable and economically viable production compared to Lithium Niobate on Insulator (LNOI). Moreover, LiTaO₃ offers a considerably lower birefringence than LiNbO₃, a key property that facilitates the design of high-density photonic circuits while ensuring broadband operation across all telecommunication bands. These characteristics make LTOI a promising platform for next-generation integrated photonic devices.

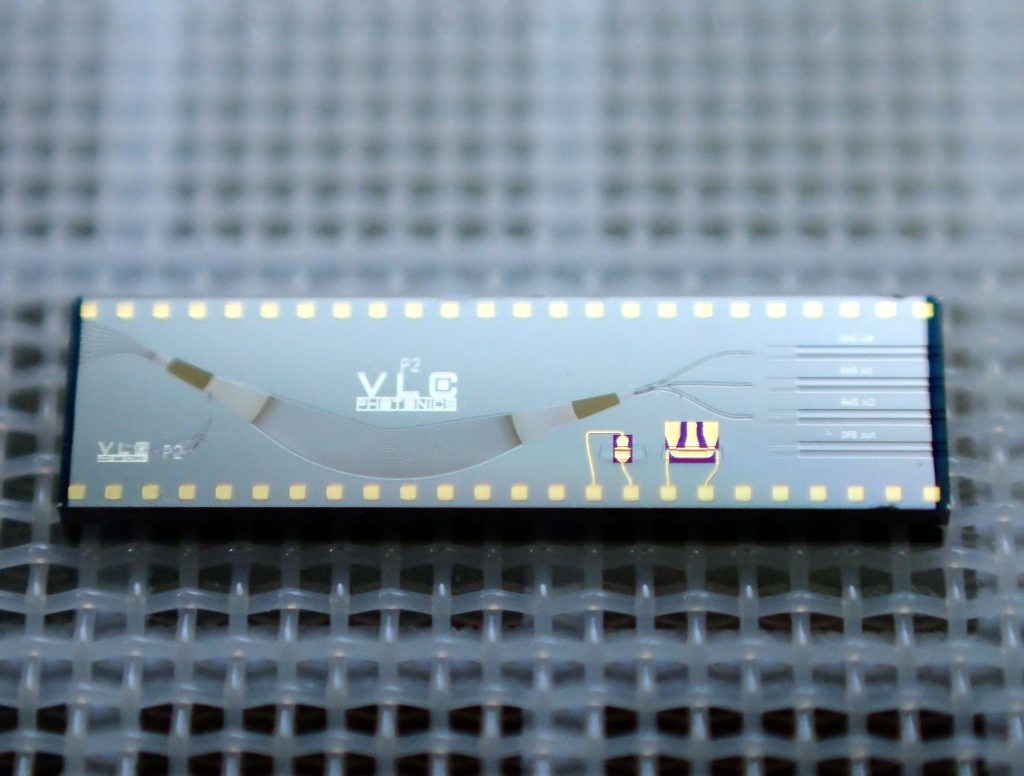

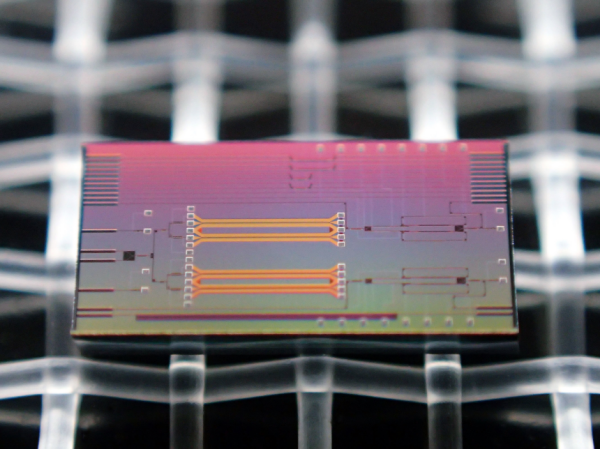

● Indium Phosphide (InP): As a direct bandgap III-V semiconductor, indium phosphide excels in integrating active photonic components such as lasers, amplifiers, modulators, and photodetectors. The bandgap of InP, corresponding to wavelengths around 1340 nm, aligns perfectly with telecommunication needs, while its compatibility with ternary and quaternary compounds like InGaAsP and InAlAs extends its operational range to 1200–2000 nm. Fabrication involves the epitaxial growth of multiple quantum wells (MQWs) or quantum dots (QDs), creating active regions for efficient light generation. Despite its advantages, the brittle nature of InP and its complex manufacturing processes limit wafer sizes to 50–100 mm, posing challenges for large-scale production.

● Barium Titanate (BaTiO₃): Barium titanate (BaTiO₃) is gaining attention as a next-generation material for photonic integration due to its remarkable electro-optic (EO) properties. Leveraging the Pockels effect, BaTiO₃ enables highly efficient, high-speed electro-optic modulation, outperforming traditional Si-based modulators in terms of modulation efficiency and power consumption.

Thin-film BaTiO₃ layers are typically integrated into silicon photonics using molecular wafer bonding, a scalable approach compatible with standard CMOS fabrication processes. This method ensures seamless integration above the back-end-of-line (BEOL) of photonic integrated circuits. BaTiO₃’s high EO coefficients enable phase shifters with unparalleled linearity, minimal optical losses, and ultra-low power consumption (<100 nW), making it ideal for applications such as RF photonics, LiDAR, and high-speed communication systems. Unlike alternatives like lithium niobate (LiNbO₃), BaTiO₃ offers better scalability to large wafers (200 mm) and superior compatibility with hybrid and monolithic integration.

● Silicon Carbide (SiC): Silicon carbide (SiC) has emerged as a versatile platform for photonic integration, offering a unique combination of properties including a wide bandgap (3.2 eV for 4H-SiC), high refractive index (~2.6), and transparency from the visible to mid-infrared range (0.4–6 μm). These properties make SiC suitable for applications in quantum photonics, nonlinear optics, and harsh-environment sensing.

SiC’s third-order optical nonlinearity (χ³) enables efficient wavelength conversion, while its second-order nonlinearity (χ²) supports frequency doubling and parametric down-conversion for quantum light sources. The material’s mechanical robustness and high thermal conductivity make it ideal for high-power photonics. SiC is compatible with CMOS processes, and platforms like silicon carbide on insulator (SiCOI) have been developed to facilitate wafer-scale integration. Challenges include reducing defect densities and optical losses through advanced epitaxial growth and fabrication techniques.

● Germanium Antimony (GeSb): Germanium antimony (GeSb) represents an advanced material platform for mid-infrared photonics, uniquely suited for high-performance optoelectronic applications. Its phase-change properties allow for a dynamic tuning of optical characteristics, such as refractive index and absorption, making it an essential material for reconfigurable photonic devices and memory applications.

The mid-infrared transparency range of GeSb, spanning from 2 to 12 μm, is particularly advantageous for sensing, environmental monitoring, and thermal imaging applications. GeSb’s unique ability to transition between amorphous and crystalline states provides a foundation for novel applications in integrated photonic switches and modulators. Its high refractive index contrast supports compact waveguide designs with efficient light confinement and propagation. Moreover, GeSb’s compatibility with CMOS processes facilitates its integration into existing silicon-based photonic platforms, enhancing scalability and cost-effectiveness. GeSb-based devices have demonstrated excellent thermal stability and durability, critical for harsh-environment sensing and long-term operation.

● Graphene: Graphene, a two-dimensional material consisting of a single atomic layer of carbon atoms arranged in a honeycomb lattice, has emerged as a revolutionary material in photonic integration. Its unique electrical and optical properties make it highly suitable for optical modulators and mid-infrared emitters. Graphene’s semimetallic nature allows for dynamic control of its optical conductivity through electrical gating, enabling tunable interaction with light. This property is exploited in graphene-based optical modulators, where an applied voltage adjusts the carrier concentration in graphene, thereby modulating light intensity. Graphene-coated silicon-on-insulator (SOI) waveguides have demonstrated effective intensity modulation at communication wavelengths of 1.55 μm.

In addition to modulators, graphene has shown promise as a mid-infrared emitter for gas sensing and environmental monitoring. When integrated directly onto waveguides, graphene can couple thermal emissions into the waveguide’s fundamental mode with high efficiency, particularly in the “fingerprint region” of the mid-IR spectrum (3–5 μm). This integration enables cost-effective, broadband mid-IR sources for photonic integrated circuits. Graphene’s high thermal stability supports operation at temperatures up to 1000 °C, making it ideal for robust applications. Coupling efficiencies as high as 68% have been achieved, surpassing other waveguide-integrated emitters. These properties position graphene as a versatile and cutting-edge material for next-generation photonic devices.

Emerging trends in photonic integration platforms

Emerging materials and hybrid integration approaches are reshaping the landscape of photonic platforms. Perovskites, vanadium oxide, and piezoelectric materials like PZT on SiN are enabling novel applications in sensing, telecommunications, and quantum technologies. The trend toward multi-material integration, which combines passive and active platforms, is expected to dominate future developments, addressing specific requirements for bandwidth, power efficiency, and integration density.

Conclusion

The diversity of photonic integration platforms reflects the tailored approaches required to meet evolving technological demands. Understanding the detailed properties and capabilities of these platforms enables researchers and engineers to design next-generation systems for telecommunications, quantum computing, sensing, and beyond. As material innovations and fabrication techniques continue to advance, photonic integrated circuits are poised to deliver transformative solutions for a wide array of scientific and industrial challenges.